Imagine an aged LDPE /EVA plant. Imagine that you are carrying out a project for an extensive revamp of the plant.

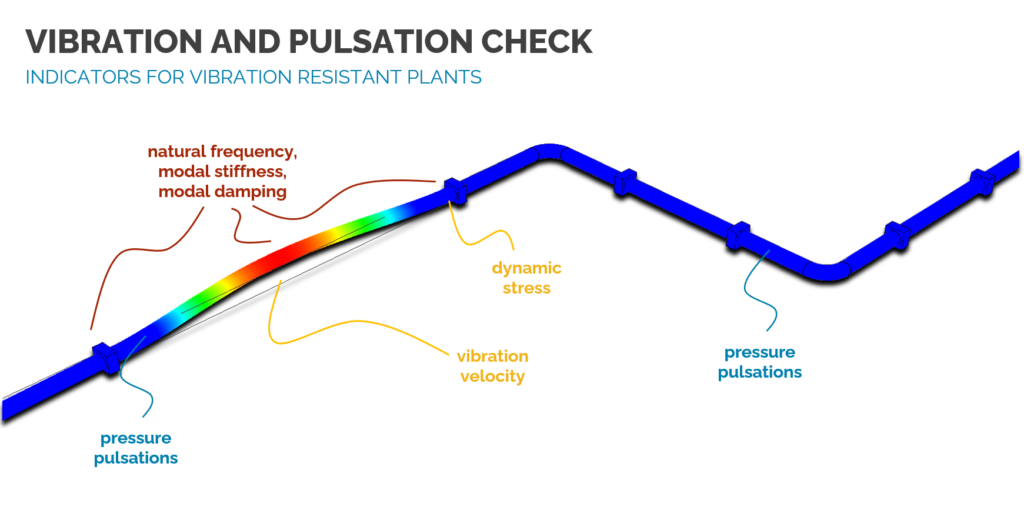

Of course you and your team have had extensive studies carried out. Ideally you have also performed a numerical check of the resulting pulsation and vibration situation.

Now the time of recommissioning is approaching. With the help of a metrological examination of the plant during normal operation it can be ensured that the dynamic load of the plant is within the expectation range and within the applicable orientation values. This can be done in a comparatively simple way for the structural vibrations. In case of doubt, you can break this indirect validation of the fatigue strength down to the dynamic material load using suitable measuring technology. In addition, you can also check the pressure pulsations in all stages of your compressor system. In this way you can be sure that no unexpected acoustic resonances in the pipes lead to a reduction in plant availability.

Get Supported.