No technical system is perfect.

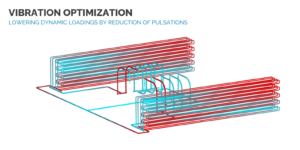

By optimising the structural mechanics and the piping acoustics of an industrial plant, significant reductions in structural vibrations can be achieved. This will improve the plants availability.

An optimisation cannot be carried out without a plan, but requires a precise definition of the original condition and the identification of a rehabilitation condition that can be achieved by economic means.

A metrological investigation enables a determination of the excitation forces and the structural-mechanical and acoustic amplification factors of a plant.

An evaluation of the different elements of this installation, based on international standards and guidelines, allows for prioritisation and helps to focus on the determining factors.

Examples

Dynamic Pipe Supports - In many cases pipe vibration are a consequence of a mechanical amplification due to a natural frequency of a pipe segment between its supports. Discharge pipe bends of hyper compressors ...

Dynamic Pipe Supports - In many cases pipe vibration are a consequence of a mechanical amplification due to a natural frequency of a pipe segment between its supports. Discharge pipe bends of hyper compressors ... Vibrations and Pulsations in High Pressure Compressor Systems - Target audience and format The target audience for this webinar are operators of LDPE/EVA plants. This full-day seminar is designed for a duration of 6 hours. A vivid discussion with ...

Vibrations and Pulsations in High Pressure Compressor Systems - Target audience and format The target audience for this webinar are operators of LDPE/EVA plants. This full-day seminar is designed for a duration of 6 hours. A vivid discussion with ... Acoustic Malfunctions in LDPE/EVA plants - 14th LDPE Plant Improvement Conference 2018 in Gdańsk, Poland: [...] An acoustic malfunction can result in fatigue failures of components, n poor compressor performance and am elevated energy consumption.

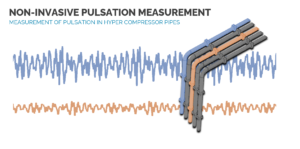

Acoustic Malfunctions in LDPE/EVA plants - 14th LDPE Plant Improvement Conference 2018 in Gdańsk, Poland: [...] An acoustic malfunction can result in fatigue failures of components, n poor compressor performance and am elevated energy consumption. Non-Invasive Measurement of Pulsations - With operating pressures up to 3,500 bar (51000 psi), LDPE plants are outstanding in the group of large chemical plants. Ethylene is compressed by a combination of different piston compressors. ...

Non-Invasive Measurement of Pulsations - With operating pressures up to 3,500 bar (51000 psi), LDPE plants are outstanding in the group of large chemical plants. Ethylene is compressed by a combination of different piston compressors. ... Optimization of a 300 kta LDPE plant - Imagine a state of the art LDPE plant. The plant has been in operation for several years and the operational experience of the owning company is high. A project to ...

Optimization of a 300 kta LDPE plant - Imagine a state of the art LDPE plant. The plant has been in operation for several years and the operational experience of the owning company is high. A project to ...