Imagine a state of the art LDPE plant. The plant has been in operation for several years and the operational experience of the owning company is high.

A project to further increase the plants availability was initiated and as a part of this project an optimization of the plants dynamic situations has been performed.

Within the scope of the investigation a non-invasive measurement of pulsations and a comprehensive vibration survey were performed.

In the interstage of b/p and secondary, elevated vibration of a pipe elbow within the recycle gas section have been identified.

The frequency of vibration was the intake frequency of the secondary compressor. The vibration affected large areas of the structures and was one of the main drivers for excessive vibrations in the plant.

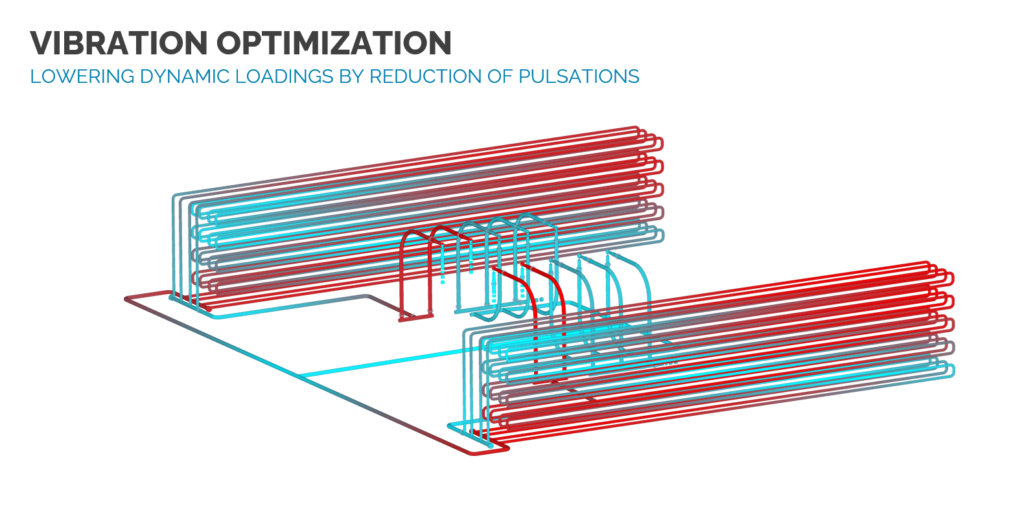

The pulsation measurement revealed a standing pressure wave in the piping system and a tuned pulsation study was performed.

By means of an optimized set of orifices a significant reduction of the pressure pulsations and the pipe vibration levels was archived.

Get Supported.