Within the framework of continuous improvement, the requirements for process and operational safety are increasing.

An important contribution in this context is the performance of ongoing external audits.

In addition to the direct assessment of the vibration-related condition on the basis of international standards and guidelines, the plant elements with degenerative behaviour (for e. g. pipe supports) will be identified and can be replaced and modified proactively.

As a further benefit of a dynamic state monitoring of a plant the owner is enabled to decide on an optimization: An assessment report will always highlight the potentials for a dynamic improvement.

Examples

Vibrations and Pulsations in High Pressure Compressor Systems - Target audience and format The target audience for this webinar are operators of LDPE/EVA plants. This full-day seminar is designed for a duration of 6 hours. A vivid discussion with ...

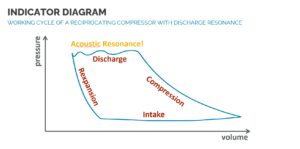

Vibrations and Pulsations in High Pressure Compressor Systems - Target audience and format The target audience for this webinar are operators of LDPE/EVA plants. This full-day seminar is designed for a duration of 6 hours. A vivid discussion with ... Acoustic Malfunctions in LDPE/EVA plants - 14th LDPE Plant Improvement Conference 2018 in Gdańsk, Poland: [...] An acoustic malfunction can result in fatigue failures of components, n poor compressor performance and am elevated energy consumption.

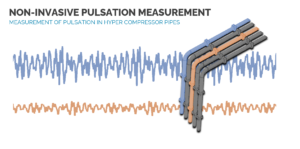

Acoustic Malfunctions in LDPE/EVA plants - 14th LDPE Plant Improvement Conference 2018 in Gdańsk, Poland: [...] An acoustic malfunction can result in fatigue failures of components, n poor compressor performance and am elevated energy consumption. Non-Invasive Measurement of Pulsations - With operating pressures up to 3,500 bar (51000 psi), LDPE plants are outstanding in the group of large chemical plants. Ethylene is compressed by a combination of different piston compressors. ...

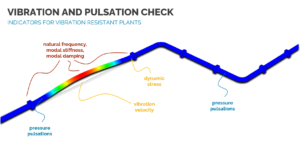

Non-Invasive Measurement of Pulsations - With operating pressures up to 3,500 bar (51000 psi), LDPE plants are outstanding in the group of large chemical plants. Ethylene is compressed by a combination of different piston compressors. ... Vibration and Pulsation Check after Revamp - With the help of a metrological examination of the plant during normal operation it can be ensured that the dynamic load of the plant is within the expectation range and within the applicable orientation values.

Vibration and Pulsation Check after Revamp - With the help of a metrological examination of the plant during normal operation it can be ensured that the dynamic load of the plant is within the expectation range and within the applicable orientation values.  Assessment of the Dynamic Condition of an EVA Plant - Imagine an aged EVA plant with a tubular reactor. The plant has been put in operation in the 1970’s and has been continuously modified and improved. After a major overhaul ...

Assessment of the Dynamic Condition of an EVA Plant - Imagine an aged EVA plant with a tubular reactor. The plant has been put in operation in the 1970’s and has been continuously modified and improved. After a major overhaul ...