A state of the art chemical plant has been subject of many theoretical studies in the engineering process. A study of vibration and a study of pulsation are mandatory for reciprocating compressor plants to ensure a proper and durable function.

Study of Pulsation

The study of pulsation is aimed on the avoidance and control of acoustic resonances in the piping which can lead to excessive dynamic forces and limit the performance.

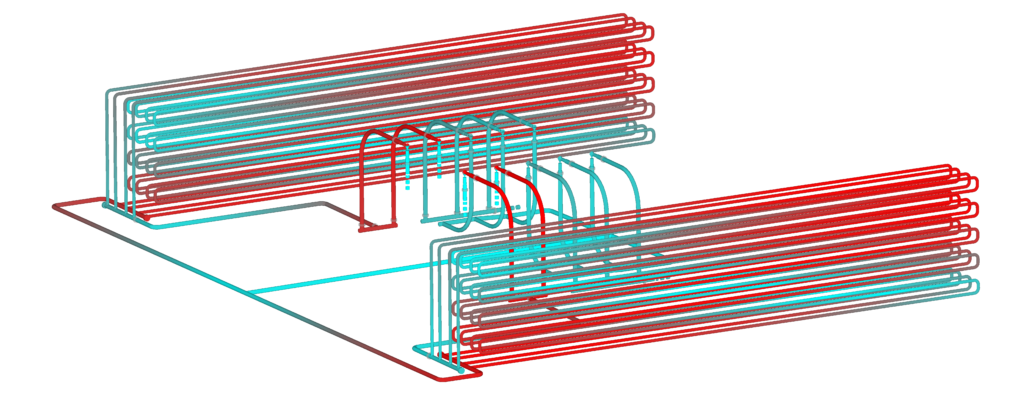

One output of this study is the estimation of the resulting dynamic forces due to the unsteady flow of a reciprocating compressor.

As a result of this study pulsation suppression devices are engineered and implemented.

The importance of this study is very high, because it allows to limit the effective dynamic forces at an early point of the chain of amplifications: forces that do not occur excessively in a system do not have to be supported by the structures later on.

Study of Vibration

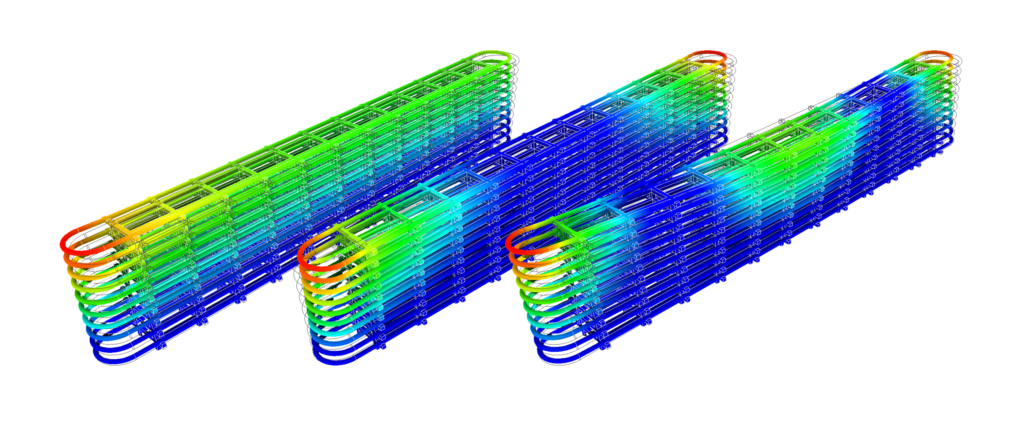

The study of vibration estimates the operational vibration level of piping, vessels and machinery due to the dynamic forces which originate from the gas pulsations and the free mass forces of the compressor. The final basis of assessment is the fatigue strength of the plant.

The accuracy of the study of vibration is limited due to the large impact of rather unkown boundary conditions like damping and as-build conditions of the structural supports.

When a metrological investigation indicates a mechanical resonance issue of a plant a small-scale study of vibration of the affected structures can provide a powerful tool to develop effective mitigation measures.