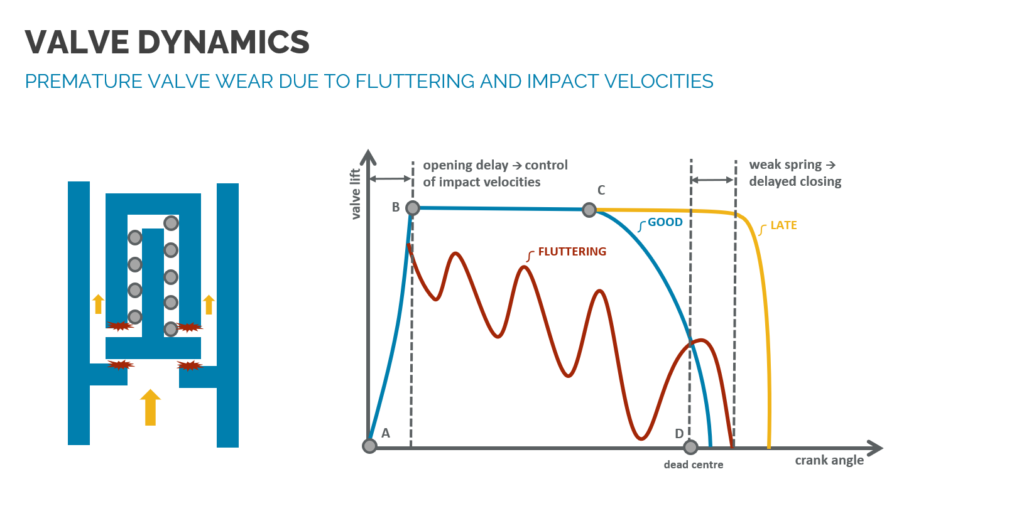

The suction and discharge valves of a hyper compressor are subject to intensive mechanical loads. To ensure a proper lifetime of these valves the closing and opening dynamics need to be well tuned. Of severe importance are the impact velocities of the valve poppet at the shutter guide and the valve seat.

The limits for impact velocities are depending on material and design parameters. The dynamic behaviour of a valve is controlled by means of a spring. The selection of the right spring stiffness is vital for a proper function and this a core competence of the valve manufacturer. A weak spring will cause failures of the valves due to excessive impacting at the shutter guide and it will lead to a delayed valve closing. This results in a flow reversal causing an excessive impact when the valve poppet returns to its seat.

By nature, poppet and spring form an oscillator. Due to the unsteady flow in a reciprocating compressor system and as a consequence of standing waves and elevated pressure pulsations in these systems a fluid structure interaction might occur. The resulting undefined motion of the valve poppet is called fluttering. This phenomenon is typical when a spring to stiff is used.

In a state-of-the art LDPE plant a poor lifetime of a compressor valve can cause severe production losses due to the high production capacities. By means of pulsation measurements and a tuned pulsation study this type of malfunction can be revealed and effective countermeasures can be identified.

Imagine a newly commissioned state of the art LDPE plant where the suction valves of the second stage are failing within hour and days

A measurement of high frequency pulsations in the suction piping by means of a non-invasive technique reveals the presence of unexpected pressure fluctuations. A theoretical analysis yields evidence for a standing pressure wave in the system, which is caused by a pulsation control device. This imposes an elevated dynamic load on the valves.

An adjustment of the pipe acoustics increases the compressor valve lifetime significantly.

Get Supported.